Grain Drying Tower

Machine type:HKB-100 Easy operation

Easy operation High efficiency

High efficiency Environmental protection

Environmental protectionHKB grain drying tower commonly used in large-scale grain storage project. Applies to variety grain high-quality drying, such as paddy rice, sorghum, soybeans, corn, and wheat, etc.

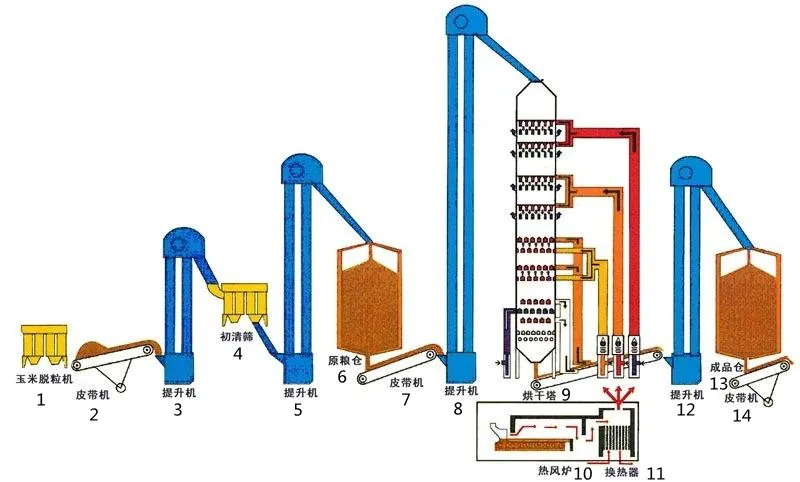

Full Set of Process Drawings

1.Corn Thresher→2.Conveyor→3.Bucket Elevator→4.Pre-Cleaner→5.Bucket Elevator→6.Original Product Silo→7.Conveyor→8.Bucket Elevator→9.Dryer Tower→10.Fuenace→11.Heat Exchanger→12.Bucket Elevator→13.Finished Product Silo→14.Conveyor

.jpg)

The rice dryer model adopts a mixed flow drying process, with multiple slow-down sections, a long grain drying process, a large precipitation range for a single machine, and a low-temperature drying process to ensure the quality of rice, and the rate of rice bursting after drying is increased. Less than 1.5%, uniform precipitation. Equipped with exhaust gas recovery device, all the cooling exhaust gas is recovered, the heat utilization rate of the whole machine is high, and the coal is saved by 7-8%. The rice dryer adopts a unique process layout, the total installed capacity is reduced, and electricity can be saved by 30-40% under the same production capacity.

Performance Features

* Mechanized continuous operation, stable performance, easy to operate, saving land construction

* Strong adaptability, can take into varieties of grain drying.

* Complete and uniform drying kinds of grain, dried grain can comes to silo directly.

* The dried grain is of high quality, no cracking, no burning, no broken, no pollution, etc.

* Patent design of discharging ensures no grain residue and can be controlled and adjusted the discharging speed.

* Original dedusting technology for exhaust gas collecting and processing, environment friendly.

.jpg)

(1).jpg)

Wet Grain Feeding 1.Host Feeding Silo

↓

2.Host Feeding Silo

↓

3.Dryer Drying Section7.Hot Air Stove6.Hot Air Duct 8.Fan9.Fan Duct

↓

4.Feeding Mechanism

↓

5.Discharge Hopper→Conveyor to Steel Silo

10.Dust Removal Room, Electric Control Room

11.Floor

12.Host Reinforced Concrete Foundation

13.Fan Derrick

| Model | HKB100 | HKB150 | HKB200 | HKB300 | HKB400 | HKB500 | HKB600 |

|---|---|---|---|---|---|---|---|

| Capacity(T/D) | 100 | 150 | 200 | 300 | 400 | 500 | 600 |

| Moisture Expected Lowed Down(%) | 3-5 | ||||||

| Heated Media | Cleaning Air | ||||||

| Heated Air Tempereture(℃) | <65 | ||||||

| Maximum Heating Tempereture(℃) | 35 | ||||||

| Drying Evenness(%) | >98 | ||||||

| Unit Heat Consumption(kj/kgH2O) | 5450-6700 | ||||||

| Coal Consumption(Standard)(kg/h) | 110-180 | 160-260 | 230-350 | 340-520 | 450-680 | 560-850 | 700-1000 |

| Installation Capacity | According to the envvironment, conditions, expected moisture lowed down and configuration. | ||||||

| Dryer Size(M) | 4*3 | 4*3 | 5.5*3.2 | 5.5*4 | 5.5*4 | 6.2*6 | 6.2*6 |

| Dryer Height(M) | 9-12 | 12-15 | 14-17 | 16-18.5 | 18-20 | 16-19 | 18-21 |