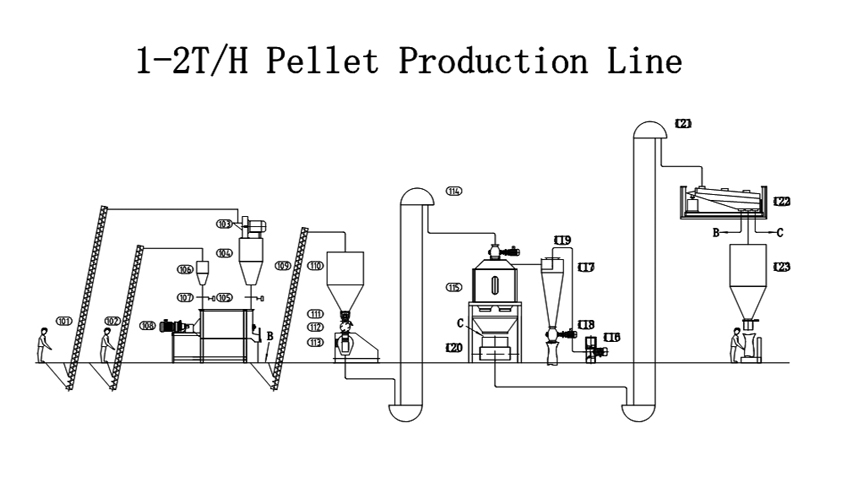

Poultry Feed Pellet Making Line

Machine type:SZLH350

|

The crusher used in the feed pellet production line is mainly used to crush raw materials into suitable particle sizes for subsequent processing and production. The crusher can break down the raw materials into smaller particles, which improves the uniformity and flowability of the particles and facilitates subsequent mixing and pressing. Can be adjusted by changing the screen or adjusting the tool clearance. |

| The feed mixer has a high mixing uniformity and can mix different materials with different proportions evenly, which ensures the consistency and stability of the feed quality. The feed mixer adopts a unique mixing structure, which can achieve rapid and efficient mixing of materials in a short time, reducing production costs and improving production efficiency. |  |

|

The main function of the feed pellet mill is to compress and shape various raw materials into uniform feed pellets of the desired size and shape. Can process various materials such as corn, wheat, soybean meal, and other grains and protein sources, as well as mineral and vitamin additives, to produce high-quality feed pellets for different animals. The feed pellet mill can adjust the pellet size according to the needs of different animals and breeding stages, which improves the feed utilization rate and reduces feed waste. |

| The main function of the feed cooler is to cool the hot and moist feed pellets from the pellet mill, reduce their temperature and moisture content, and increase their hardness and stability. Adopts a counterflow cooling principle, which can achieve high cooling efficiency and reduce the breakage rate of the pellets. Can adjust the cooling temperature according to the needs of different types of feed pellets, which improves the quality of the feed pellets and reduces energy consumption. |  |

|

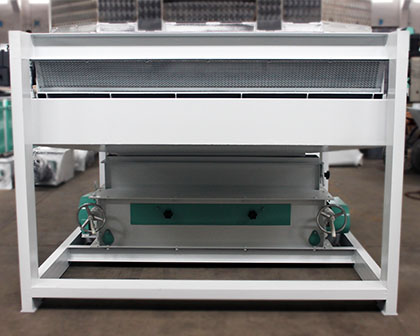

The main function of the feed grading sieve equipment is to classify and screen the feed pellets according to their size, which improves the quality of the feed pellets and increases their market value. Adopts a precision screening system, which can accurately classify and screen the feed pellets of different sizes, ensuring the consistency and stability of the feed quality. Can classify and screen various types of feed pellets, such as poultry feed, aqua feed, and pet feed, and can be customized according to specific production requirements. |

| The feed grading and screening equipment is used to screen out the unqualified pellets or powder from the final products. It has a high screening accuracy and a low noise level. Can separate different sizes of pellets by using different meshes. |  |

|

The main function of the feed pellet packaging machine is to automatically pack feed pellets into bags of various sizes, which improves the efficiency of the feed pellet production line and reduces labor costs. Can pack various types of feed pellets, such as poultry feed, aqua feed, and pet feed, and can be customized according to specific production requirements. |

The biomass pellet machine is a device that processes materials such as paulownia, cypress, poplar, fruitwood, agricultural crop straw, bamboo shavings, etc., by crushing them into sawdust-like bran and then processing them into biomass fuel.

Due to variations in raw materials used in different regions, the biomass pellet machine is known by different names such as wood pellet machine, straw pellet machine, sawdust pellet machine, wood chip pellet machine, bamboo pellet machine, fuel pellet machine, rice husk pellet machine, etc. It is also referred to as a pelletizer or pellet maker. Despite the differences in terminology, they all refer to the same type of machine.

Based on the type of die used, it can be further categorized into flat die pellet machine and ring die pellet machine. The ring die pellet machine can be further classified into vertical ring die pellet machine and horizontal ring die pellet machine.

According to the working principle of the feed pellet machine, it can be classified into die roller pellet machine and screw extrusion pellet machine. According to the purpose of the feed pellet machine, it can be classified into single-feed pellet machine and mixed-feed pellet machine.

| Model | SZLH250 | SZLH350 | SZLH400 | SZLH420 | SZLH508 | SZLH578 | SZLH678 | SZLH768 |

| Capacity(t/h) | 1-2 | 2-8 | 3-12 | 3-15 | 5-20 | 8-22 | 10-30 | 10-38 |

| Power(kw) | 22 | 55 | 75-90 | 90-110 | 110-160 | 160-200 | 200-250 | 250-315 |

.jpg)