Animal feed pellet machine

Machine type:SZLH250

Product introduce:SZLH Series Ring Mould Aniamal Feed Pellet Machine is the main chicken feed machine of making granular fodder, it can be used to make various roughage andrefined fodder in livestock farm and feed mill, and also used for checmical industry, fertilizer

Use range:The Animal feed pellet machine can use grain, corn, soybean meal, grass, straw, corn straw, wheat straw, crop straw, sorghum straw, wheat straw, alfalfa, hemp, hops and other agricultural raw materials to produce livestock and poultry feed, ruminant feed, fish feed and so on.

Performance characteristics

Product introduction

SZLH Series Ring Mould Aniamal Feed Pellet Machine is the main chicken feed machine of making granular fodder, it can be used to make various roughage andrefined fodder in livestock farm and feed mill, and also used for checmical industry, fertilizer industry and sugar industry. press pellet machine pellet feed processing machine poultry pellet feed machine

Aniamal Feed Pellet Machine is suitable for use in farms , with good quality , high efficiency , save engry. Convenient operation, reliable sealing, high production rate, low power consumption, low labor strength. animal pellet feed machine.

Working principle

Working Process of Animal feed pellet machine

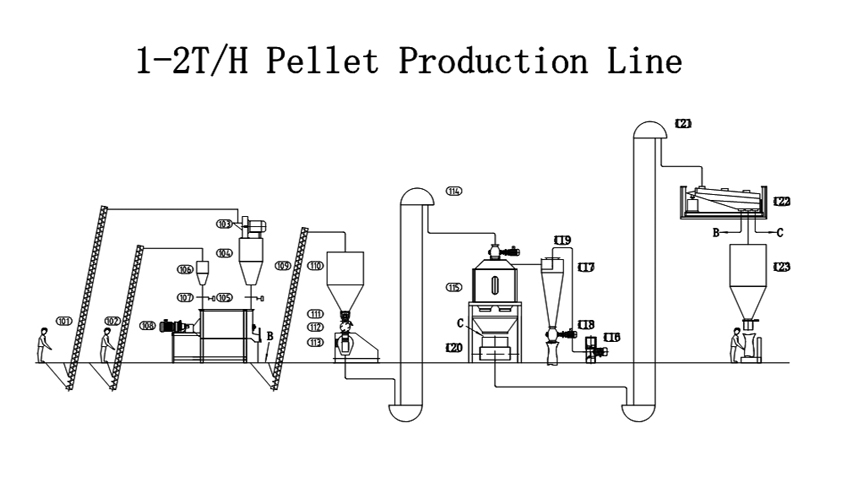

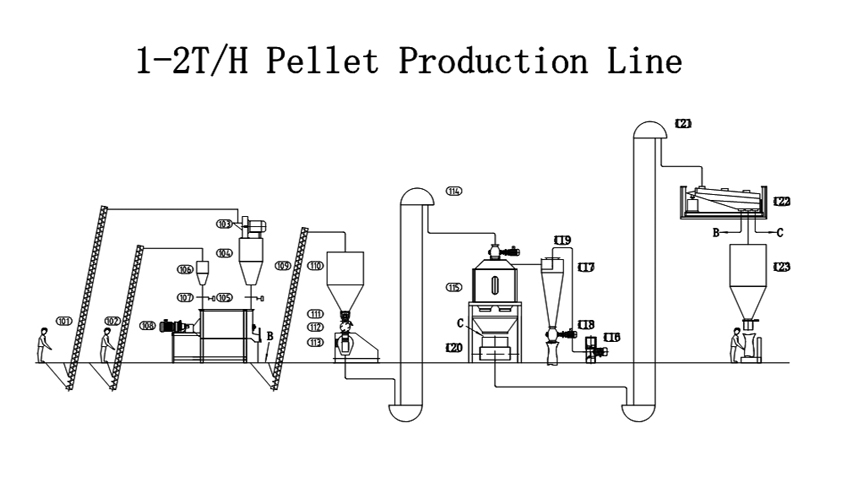

Technological procedure:

Starting Materials → mixing → transferring → extrusion puffing → transferring → drying → cooling → screening → spraying oil →seasoning → packaging

Equipment configuration

Mixer → transfer unit → extruder → elevator → dryer → cooler → vibrating screen → elevator → oil spraying machine → automatic packaging machine

1、Coban Animal feed pellet machine has the latest technology adopted toproduct many kinds of feed.

2、The bearings ,oil seal, O-Rings of the drive part are all import.

3、The design, quality and facade of the machine is inthe international advanced level.

4、The main drive part uses high-precision gearrevolve, with this the production improved 15-20%.5、The gear revolve uses high precision gear grindingreduced the vibration and strepitus.

6、The outside painting is sprayed. light and fastness

7、lt improves the effciency and reduces the labourintensity.

8、The material of conditioning system is stainless steesantitary, the service time of it extend.

9、There are several air inlets to add steam, it made thematerial heated enough , the effect of it is better.

10、The engine oil circulating cooling lubricationsystem improves the cooling and lubrication effect of thekey bearings.

|

The feed crusher adopts water drop shredder chamber, ultra-wide crushing chamber, discharge output, secondary U stroke design, reverse circulation design, complete opening, etc. The chain link pressure control mechanism is easy to operate. |

| Feed mixer there are 2 types of feed mixer used in feed pellet production line: horizontal belt mixer and two-shaft blade batch mixer. The first is the most commonly used and saves energy; the second can add liquid. |

|

|

The Animal feed pellet machine is equipped with automatic fatliquoring system, stainless steel feeder and imported frequency converter control. You can also choose a single feed granulator and a dual feed pellet mill. |

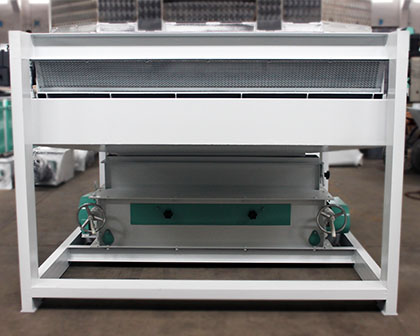

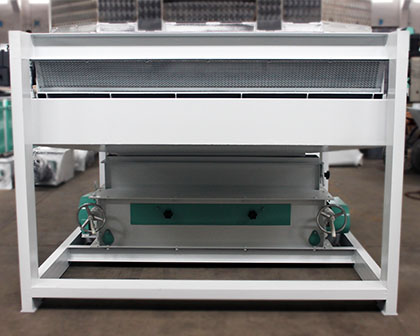

| The feed pellet cooling machine adopts octagonal cooling chamber with no cooling dead angle. Countercurrent design can prevent feed particles from being damaged by direct contact with cold air. The cooler is installed above the crusher |

|

|

The feed pellets crumbler crushes the large pellet feed into small particles to meet the feeding of small animals, such as chicks, piglets and lambs. This method can reduce the production cost of the whole feed pellet, and it is easier to produce small pellet feed. |

| The feed grading and screening equipment classifies the cooled and crushed particles so that the qualified feed particles carry out the subsequent packaging process, while the large particles or powder are recycled to the granulation or crushing process. |

|

|

Feed packaging machine has automatic packaging machine and manual packaging machine for you to choose from. It usually consists of weights and measures, bag sewing machine, conveyor belt and so on. |

Technical parameters

| Model |

SZLH250 |

SZLH350 |

SZLH400 |

SZLH420 |

SZLH508 |

SZLH578 |

SZLH678 |

SZLH768 |

| Capacity(t/h) |

1-2 |

2-8 |

3-12 |

3-15 |

5-20 |

8-22 |

10-30 |

10-38 |

| Power(kw) |

22 |

55 |

75-90 |

90-110 |

110-160 |

160-200 |

200-250 |

250-315 |

.jpg)

Technical parameters change, no further notice.

Relative equipment

Material

Case

.jpg)