Poultry Feed Pellet Making Line

Machine type:SZLH350

Product introduce:Are you looking for a high-quality and cost-effective Poultry Feed Pellet Making Line?

Do you want to produce various kinds of feed pellets for different animals? If yes, then you have come to the right place!

We are a professional manufac

Use range:Poultry Feed Pellet Making Line can use grain, corn, soybean meal, grass, straw, corn straw, wheat straw, crop straw, sorghum straw, wheat straw, alfalfa, hemp, hops and other agricultural raw materials to produce livestock and poultry feed, ruminant feed, fish feed and so on.

Performance characteristics

Product introduction

Are you looking for a high-quality and cost-effective Poultry Feed Pellet Making Line?

Do you want to produce various kinds of feed pellets for different animals? If yes, then you have come to the right place!

We are a professional manufacturer and supplier of Poultry Feed Pellet Making Line, with more than 20 years of experience in the industry. We can provide you with a complete solution for your feed pellet needs, from raw material processing, mixing, pelleting, cooling, and packing, to after-sales service.

Working principle

Poultry Feed Pellet Making Line

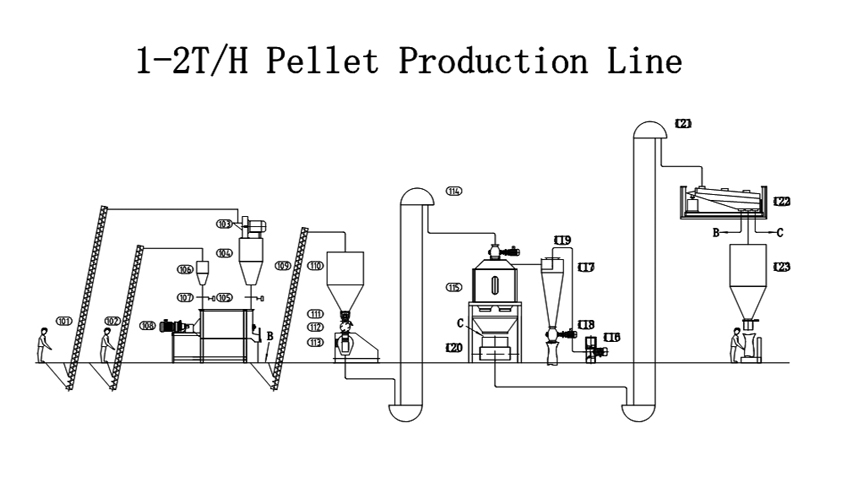

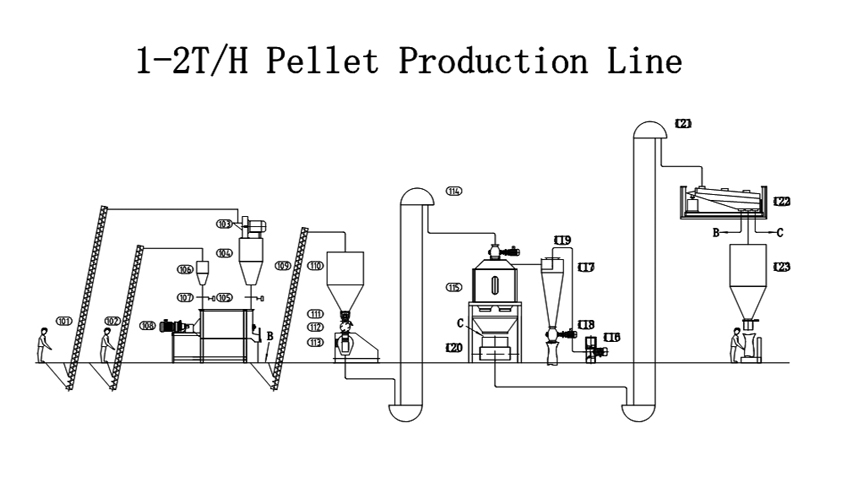

Working Process of Poultry Feed Pellet Making Line

Technological procedure:

Starting Materials → mixing → transferring → extrusion puffing → transferring → drying → cooling → screening → spraying oil →seasoning → packaging

Equipment configuration

Mixer → transfer unit → extruder → elevator → dryer → cooler → vibrating screen → elevator → oil spraying machine → automatic packaging machine

1、Coban Poultry Feed Pellet Making Line has the latest technology adopted toproduct many kinds of feed.

2、The bearings ,oil seal, O-Rings of the drive part are all import.

3、The design, quality and facade of the machine is inthe international advanced level.

4、The main drive part uses high-precision gearrevolve, with this the production improved 15-20%.

5、The gear revolve uses high precision gear grindingreduced the vibration and strepitus.

6、The outside painting is sprayed. light and fastness

7、lt improves the effciency and reduces the labourintensity.

8、The material of conditioning system is stainless steesantitary, the service time of it extend.

9、There are several air inlets to add steam, it made thematerial heated enough , the effect of it is better.

10、The engine oil circulating cooling lubricationsystem improves the cooling and lubrication effect of thekey bearings.

|

The crusher used in the feed pellet production line is mainly used to crush raw materials into suitable particle sizes for subsequent processing and production. The crusher can break down the raw materials into smaller particles, which improves the uniformity and flowability of the particles and facilitates subsequent mixing and pressing. Can be adjusted by changing the screen or adjusting the tool clearance. |

| The feed mixer has a high mixing uniformity and can mix different materials with different proportions evenly, which ensures the consistency and stability of the feed quality. The feed mixer adopts a unique mixing structure, which can achieve rapid and efficient mixing of materials in a short time, reducing production costs and improving production efficiency. |

|

|

The main function of the feed pellet mill is to compress and shape various raw materials into uniform feed pellets of the desired size and shape. Can process various materials such as corn, wheat, soybean meal, and other grains and protein sources, as well as mineral and vitamin additives, to produce high-quality feed pellets for different animals. The feed pellet mill can adjust the pellet size according to the needs of different animals and breeding stages, which improves the feed utilization rate and reduces feed waste. |

| The main function of the feed cooler is to cool the hot and moist feed pellets from the pellet mill, reduce their temperature and moisture content, and increase their hardness and stability. Adopts a counterflow cooling principle, which can achieve high cooling efficiency and reduce the breakage rate of the pellets. Can adjust the cooling temperature according to the needs of different types of feed pellets, which improves the quality of the feed pellets and reduces energy consumption. |

|

|

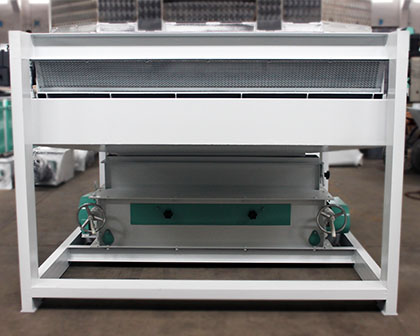

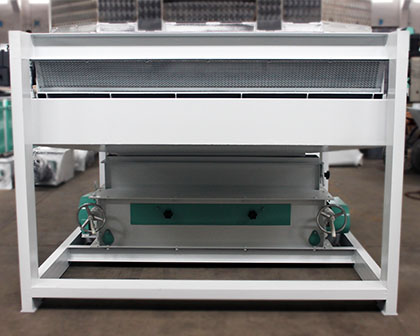

The main function of the feed grading sieve equipment is to classify and screen the feed pellets according to their size, which improves the quality of the feed pellets and increases their market value. Adopts a precision screening system, which can accurately classify and screen the feed pellets of different sizes, ensuring the consistency and stability of the feed quality. Can classify and screen various types of feed pellets, such as poultry feed, aqua feed, and pet feed, and can be customized according to specific production requirements. |

| The feed grading and screening equipment is used to screen out the unqualified pellets or powder from the final products. It has a high screening accuracy and a low noise level. Can separate different sizes of pellets by using different meshes. |

|

|

The main function of the feed pellet packaging machine is to automatically pack feed pellets into bags of various sizes, which improves the efficiency of the feed pellet production line and reduces labor costs. Can pack various types of feed pellets, such as poultry feed, aqua feed, and pet feed, and can be customized according to specific production requirements. |

Our Poultry Feed Pellet Making Line has a strict quality control system to ensure the quality of each machine and each product. We have a professional quality inspection team to check every machine before delivery. We also have a laboratory to test every batch of products for their physical and chemical properties. Our Poultry Feed Pellet Making Line has a fast delivery time and a convenient transportation mode. We have a large stock of machines and spare parts in our warehouse. We can deliver the machines within 30 working days after receiving your deposit. We can also arrange sea or air transportation according to your preference.

Technical parameters

| Model |

SZLH250 |

SZLH350 |

SZLH400 |

SZLH420 |

SZLH508 |

SZLH578 |

SZLH678 |

SZLH768 |

| Capacity(t/h) |

1-2 |

2-8 |

3-12 |

3-15 |

5-20 |

8-22 |

10-30 |

10-38 |

| Power(kw) |

22 |

55 |

75-90 |

90-110 |

110-160 |

160-200 |

200-250 |

250-315 |

.jpg) Company

Company

We are a professional manufacturer and supplier of Poultry Feed Pellet Making Line, with more than 20 years of experience in the industry. We can provide you with a complete solution for your feed pellet needs, from raw material processing, mixing, pelleting, cooling, and packing, to after-sales service.

We are a professional manufacturer and supplier of Poultry Feed Pellet Making Line, with more than 20 years of experience in the industry. We can provide you with a complete solution for your feed pellet needs, from raw material processing, mixing, pelleting, cooling, and packing, to after-sales service.

Technical parameters change, no further notice.

Relative equipment

Material

Case

.jpg)