Animal Feed Machinery In Kenya

Machine type:SZLH350

Product introduce:Animal Feed Machinery In Kenya are an essential component of the animal feed industry, providing a cost-effective and efficient way to produce high-quality feed pellets for livestock and poultry.

Our equipment is made from high-quality materials a

Use range:Can use grain, corn, soybean meal, grass, straw, alfalfa, etc, to produce livestock and poultry feed, ruminant feed, fish feed and so on.

Performance characteristics

Product introduction

Animal Feed Machinery In Kenya are an essential component of the animal feed industry, providing a cost-effective and efficient way to produce high-quality feed pellets for livestock and poultry.

Our equipment is made from high-quality materials and is built to withstand the demands of continuous use, ensuring reliable operation and long-term performance. Our feed pellet production lines are available in a range of sizes, from small-scale production lines suitable for small farms and feed mills to large-scale production lines capable of producing hundreds of tons of feed pellets per day.

Working principle

Animal Feed Machinery In Kenya

Starting Materials → mixing → transferring → extrusion puffing → transferring → drying → cooling → screening → spraying oil →seasoning → packaging

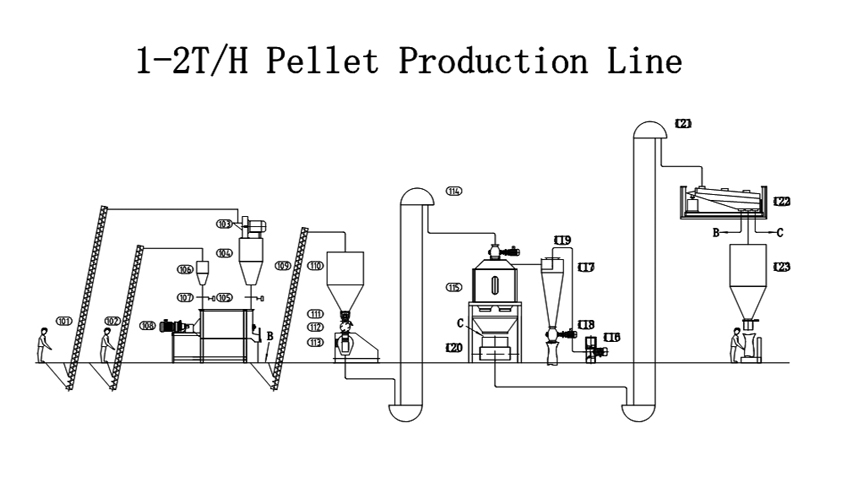

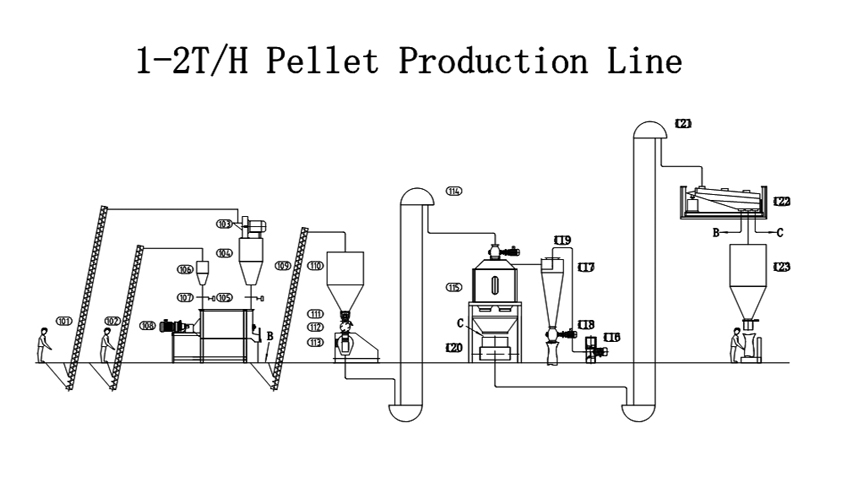

Equipment configuration

Mixer → transfer unit → extruder → elevator → dryer → cooler → vibrating screen → elevator → oil spraying machine → automatic packaging machine

1、The latest technology adopted toproduct many kinds of feed.

2、The bearings ,oil seal, O-Rings of the drive part are all import.

3、The design, quality and facade of the machine is inthe international advanced level.

4、The main drive part uses high-precision gearrevolve, with this the production improved 15-20%.

5、The gear revolve uses high precision gear grindingreduced the vibration and strepitus.

6、The outside painting is sprayed. light and fastness

7、lt improves the effciency and reduces the labourintensity.

8、The material of conditioning system is stainless steesantitary, the service time of it extend.

9、There are several air inlets to add steam, it made thematerial heated enough , the effect of it is better.

10、The engine oil circulating cooling lubricationsystem improves the cooling and lubrication effect of thekey bearings.

The crusher is mainly used to crush raw materials into suitable particle sizes for subsequent processing and production. It can break down the raw materials into smaller particles, which improves the uniformity and flowability of the particles and facilitates subsequent mixing and pressing.

The feed mixer has a high mixing uniformity and can mix different materials with different proportions evenly, which ensures the consistency and stability of the feed quality. It adopts a unique mixing structure, which can achieve rapid and efficient mixing of materials in a short time.

The feed pellet mill is to compress and shape various raw materials into uniform feed pellets of the desired size and shape. Can process various materials such as corn, wheat, soybean meal, and other grains and protein sources, as well as mineral and vitamin additives, to produce high-quality feed pellets for different animals.

The feed pellet mill is to compress and shape various raw materials into uniform feed pellets of the desired size and shape. Can process various materials such as corn, wheat, soybean meal, and other grains and protein sources, as well as mineral and vitamin additives, to produce high-quality feed pellets for different animals.

The feed cooler is to cool the hot and moist feed pellets from the pellet mill, reduce their temperature and moisture content, and increase their hardness and stability. Adopts a counterflow cooling principle, which can achieve high cooling efficiency and reduce the breakage rate of the pellets.

The feed cooler is to cool the hot and moist feed pellets from the pellet mill, reduce their temperature and moisture content, and increase their hardness and stability. Adopts a counterflow cooling principle, which can achieve high cooling efficiency and reduce the breakage rate of the pellets.

The feed grading sieve equipment is to classify and screen the feed pellets according to their size. Adopts a precision screening system, which can accurately classify and screen the feed pellets of different sizes, ensuring the consistency and stability of the feed quality.

The feed grading sieve equipment is to classify and screen the feed pellets according to their size. Adopts a precision screening system, which can accurately classify and screen the feed pellets of different sizes, ensuring the consistency and stability of the feed quality.

The feed grading and screening equipment is used to screen out the unqualified pellets or powder from the final products. It has a high screening accuracy and a low noise level. Can separate different sizes of pellets by using different meshes.

The feed packaging machine is to automatically pack feed pellets into bags of various sizes. Can pack various types of feed pellets, such as poultry feed, aqua feed, and pet feed, and can be customized according to specific production requirements.

The feed packaging machine is to automatically pack feed pellets into bags of various sizes. Can pack various types of feed pellets, such as poultry feed, aqua feed, and pet feed, and can be customized according to specific production requirements.

Animal Feed Machinery In Kenya can use grain, corn, soybean meal, grass, straw, alfalfa, etc, to produce livestock and poultry feed, ruminant feed, fish feed and so on.

Animal Feed Machinery In Kenya can use grain, corn, soybean meal, grass, straw, alfalfa, etc, to produce livestock and poultry feed, ruminant feed, fish feed and so on.

Technical parameters

| Model |

SZLH250 |

SZLH350 |

SZLH400 |

SZLH420 |

SZLH508 |

SZLH578 |

SZLH678 |

SZLH768 |

| Capacity(t/h) |

1-2 |

2-8 |

3-12 |

3-15 |

5-20 |

8-22 |

10-30 |

10-38 |

| Power(kw) |

22 |

55 |

75-90 |

90-110 |

110-160 |

160-200 |

200-250 |

250-315 |

.jpg) Company

Company

Our company has a strict quality control system to ensure the quality of each machine and each product. We have a professional quality inspection team to check every machine before delivery. We also have a laboratory to test every batch of products for their physical and chemical properties.

Our company has a strict quality control system to ensure the quality of each machine and each product. We have a professional quality inspection team to check every machine before delivery. We also have a laboratory to test every batch of products for their physical and chemical properties.

Technical parameters change, no further notice.

Relative equipment

Material

Case

.jpg)